|

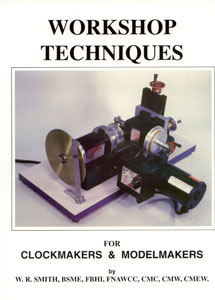

WORKSHOP TECHNIQUES for CLOCKMAKERS & MODELMAKERS by W R SMITH |

||||

| This manual contains all of the articles (except serials) written by W. R. Smith and published in The Home Shop Machinist, Projects In Metal, and England's The Clockmaker during the last eight or so years. These articles are much in demand and are no longer available from other sources. The manual is 8-1/2 x 11, 108 pages and is comb bound to lie flat. Some of the more important information contained in these articles are: How a very inexpensive and commercially available spindle can be adapted foruse on bench lathes for milling, drilling, gear cutting, etc. Details for making a fly wheel to smooth the cut, a filing rest, a saw table, a T-rest, and cross slide and vertical slide locks, all for the Sherline lathe. How to make indexing plates from first principles for indexing any type lathe and without the need for another indexing plate or dividing head. How a Sherline lathe can be used to configure itself for gear and pinion cutting and lantern pinion making without the need for a milling machine. How to make a macro mill/drill spindle from junk watchmaker's lathe headstock parts. Details for making the simple accessories required for winding music box and other heavy duty mainsprings on the bench lathe. Details for adapting the Myford and other bench lathes for use with 10 mm collets. A tip over T-rest for use on the bench lathe. The cutting of a 6" diameter, 200 tooth gear on a standard Sherline lathe (lathe only). A copy of the T-rest for the Sherline lathe is currently being manufactured by Sherline and is offered as the W. R. Smith T-rest, P/N 2110. This allows the freehand turning of small ornate shapes without the need for a making a form tool. Hand turning is also very fast. With the T-rest, one can turn a 1/16" diameter pivot, 3/16" long on 1/8" diameter hardened and tempered music wire or blue pivot steel (un-annealed), chamfer the shoulder and round the end of the pivot in less than one minute. For the first time ever, one can now use only a Sherline lathe to configure itself for cutting gears, pinions and making lantern pinions without the need of a milling machine. Because many of the things offered are very unusual and are demonstrated on Sherline equipment, this manual is a must for Sherline users. However, the techniques are basic and are equally useful on other and larger equipment. | ||||

|

|

£ p |

|

Chapters 1 - An Inexpensive Milling/Drilling Spindle 2 - A Quick Release T Rest for the Sherline Lathe 3 - A Filing Rest for the Sherline Lathe 4 - A Saw Table for the Sherline Lathe 5 - Gear Cutting on the Sherline Lathe (part 1) 6 - Gear Cutting on the Sherline Lathe (part 2) 7 - Gear Cutting on the Sherline Lathe (part 3) 8 - A Micro Milling/Drilling Spindle 9 - Adapting the Myford For Hand Turning 10 - Winding Mainsprings on the Bench Lathe 11 - Adapting the Sherline for Wheel Cutting and Pinion Making (part 1) 12 - Adapting the Sherline for Wheel Cutting and Pinion Making (part 2)

|

Back to W. Smith Clocks |

| BOOK out of stock |

|

|||

| ORDER FORM | ||||